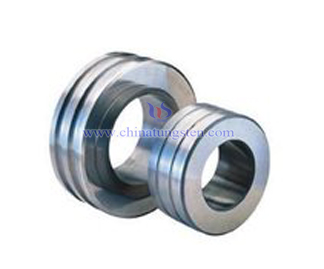

Cast-Composite Tungsten Carbide Rollers

Cast-composite tungsten carbide rollers is a composite tungsten carbide rollers important structural way. Cast-in (CIC, ie CAST IN tungsten carbide) composite tungsten carbide rollers, the technology is set within the casting together with ductile iron tungsten carbide rings. Between the rollers ring and rollers axis coupling. This connection mode, composite rollers by in the outer ring has a very high hardness and excellent wear resistance of tungsten carbide materials withstand the rolling force, in the inner layer by having good strength and toughness of ductile iron transfer torque.

Cast-composite tungsten carbide rollers production process of composite tungsten carbide ring is: sintered tungsten carbide rollers → ductile cast ductile iron metallurgy composite bore or shaft for the inner ring of tungsten carbide rollers → heat treatment to eliminate stress , machining → composite rollers or rollers. tungsten carbide and ductile iron atom diffusion bonding interface of each other to become the metallurgical complex.

Cast-composite tungsten carbide rollers structural features:

(1) Cast-composite tungsten carbide rollers with the composite layer enhances the strength and toughness of the rollers ring, can withstand large rolling load;

(2) between the use of cast-composite tungsten carbide rollers and rollers with interference fit coupling to solve the cold mounting structure is easy to bash the key issues, the rolling process is more stable;

(3) Cast-composite tungsten carbide rollers and rollers contact surface without gaps, avoiding the cooling water containing impurities on the contact surface corrosion caused by deformation of the rollers ring.

Development of cast-composite tungsten carbide rollers technology, is a new combination of powder metallurgy technology and casting technology is a major advancement in the technology of composite wear-resistant material rollers applications.